Title: LCA 4: The Environmental Assessment of Construction Materials

Concrete, steel, and aluminium – just three traditional construction materials – account for nearly 23 % of global CO₂ emissions. If current trends continue, by 2050 up to 90 % of new buildings’ emissions could come from embodied carbon alone. This highlights a crucial fact: material choice has become one of the most powerful levers for reducing our environmental impact.

From Foundations to Rooftops: Materials Matter

The environmental impact of building materials is more than a technical detail — it is a strategic issue for all stakeholders:

- Manufacturers can shape product sustainability profiles and innovate.

- Architects and engineers directly influence a project’s total carbon footprint through their material specifications.

- Developers and investors increasingly see embodied carbon as a financial and market performance indicator.

A significant reduction of environmental impacts requires a collaborative approach. Structural engineers define load-bearing systems, while manufacturers can support the transition by providing low-impact alternatives.

Growing Regulation and Market Pressure

Embodied carbon is under growing scrutiny worldwide, with EU taxonomy requiring the disclosure of Global Warming Potential (GWP) indicators, ESG frameworks demanding verified KPIs, and green building certifications (LEED, BREEAM) rewarding low-impact material choices. Businesses that proactively manage material emissions not only gain environmental credibility but also improve access to green finance and strengthen their competitive position.

Carbon Intensity and Life Cycle Categories

Life Cycle Assessment (LCA) evaluates a material’s impact across multiple categories:

- Climate change (CO₂e footprint)

- Resource use, acidification, eutrophication, ozone depletion, among others

Materials sourced from renewables or recycling typically have a lower footprint. Conversely, virgin and energy-intensive materials have a much higher impact.

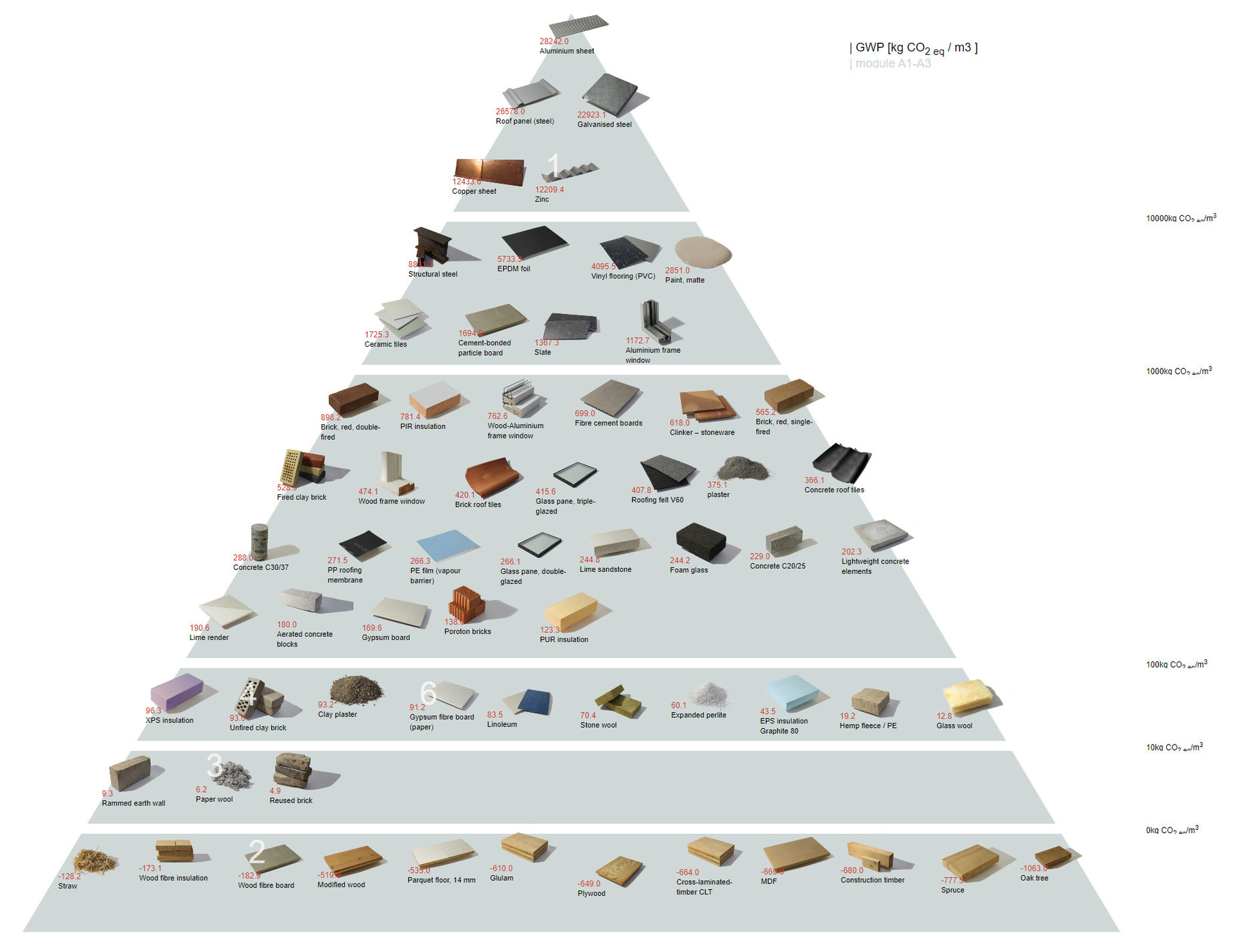

Tools and Insights: The Building Materials Pyramid

The Royal Danish Academy’s interactive Building Material Pyramid ranks materials by environmental impact. Metals sit at the top, with steel alone responsible for up to 80 % of a building’s embodied carbon in some cases. Cement-based products are also major contributors. Optimising structural design and exploring low-carbon alternatives is therefore essential.

Pathways to Reduce Embodied Carbon

There is no universal “best” material — choices must be tailored to performance requirements and local availability. Key strategies include:

- Low-carbon concrete mixes, by reducing cement content or using supplementary cementitious materials (e.g., fly ash, slag)

- Circularity: using recycled materials to lower the need for virgin resources

- Biobased materials like wood, hemp, and straw, which store biogenic carbon and offer renewable solutions for structure, insulation, and cladding

The EU-funded BIO4EEB project develops and tests biobased insulation solutions across Europe, bridging the gap between rising demand and limited production capacity.

Data Transparency and Comparability

Reliable data is critical. Environmental Product Declarations (EPDs), standardised by EN 15804, make it possible to compare products based on their full life-cycle impacts. International databases (ÖKOBAUDAT, INIES, EPD Norge, EC3) and national registries are key to transparency and scalability.

A Regulatory Shift Is Underway

EU policy (revised EPBD, Construction Products Regulation) is making LCA a core requirement, not an option. National registries, such as Hungary’s Construction Economy Register, are now centralising data to facilitate reuse and recycling, making LCA-based design and product transparency a cornerstone of future building practices.

Conclusion

LCA is no longer a niche exercise — it is becoming a standard for sustainable construction. Choosing the right materials is now a strategic decision with environmental, financial, and reputational consequences. By prioritising low-carbon, renewable, and recycled materials, the construction sector can cut embodied emissions, unlock economic opportunities, and accelerate the transition toward a truly sustainable built environment.

Authors

Dr. Amina Dacic, PhD

Associate Researcher, ABUD – Advanced Building & Urban Design

MSc in Civil Engineering, Structural Engineering Specialization (BME, Budapest)

BSc in Civil Engineering (Yeditepe University, Türkiye)

Szilvia Bősze

Managing Director & Partner, ASPA – Advanced Sustainability Performance Advisors

Agricultural Engineer in Environmental Management (SZIE)

Accredited ESG Consultant (TTAN-88-2024)

Melinda Orova

Senior Sustainability Consultant, ABUD – Advanced Building & Urban Design

M.A. in Architecture (BME)

Engineer in Urban Energy and Facilities (PTE)

LEED BD+C Accredited Professional